About

The Idea

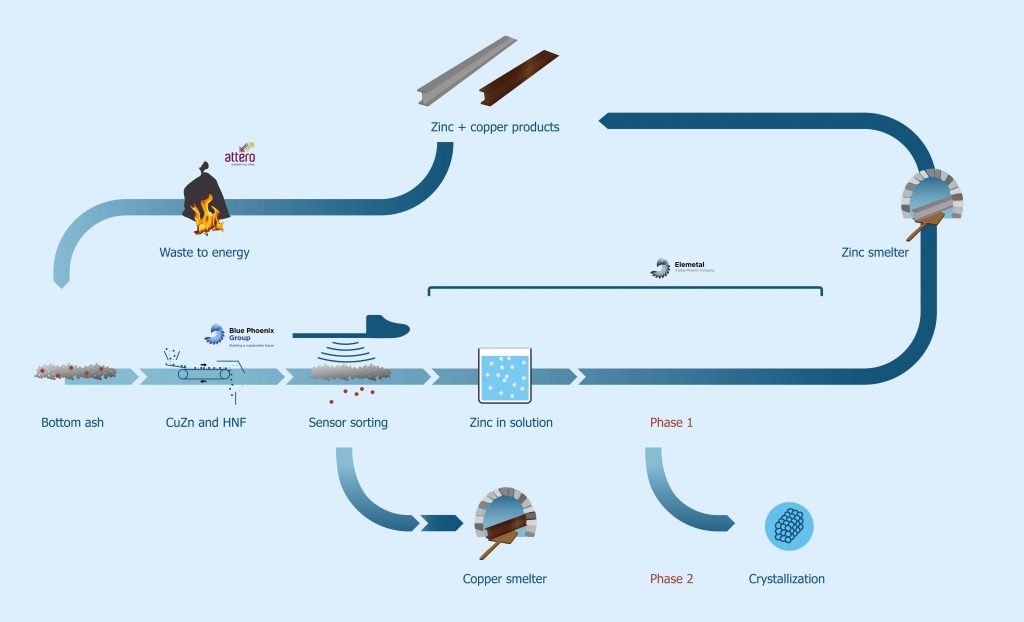

The idea of the project originated from the startup company Elemetal. As a spin-off from Delft Technical University Elemetal started with the development of a hydrometallurgical process to recover copper directly from waste-to-energy bottom ash. Bottom ash is the residue from waste-to-energy facilities and is a rich source of metals. Today bottom ash is treated by physical separation technologies like sieving, magnetic separation and eddy-current separation. These processes used to have a poor recovery on copper from the bottom ashes which resulted in the idea to look a metallurgical approach.

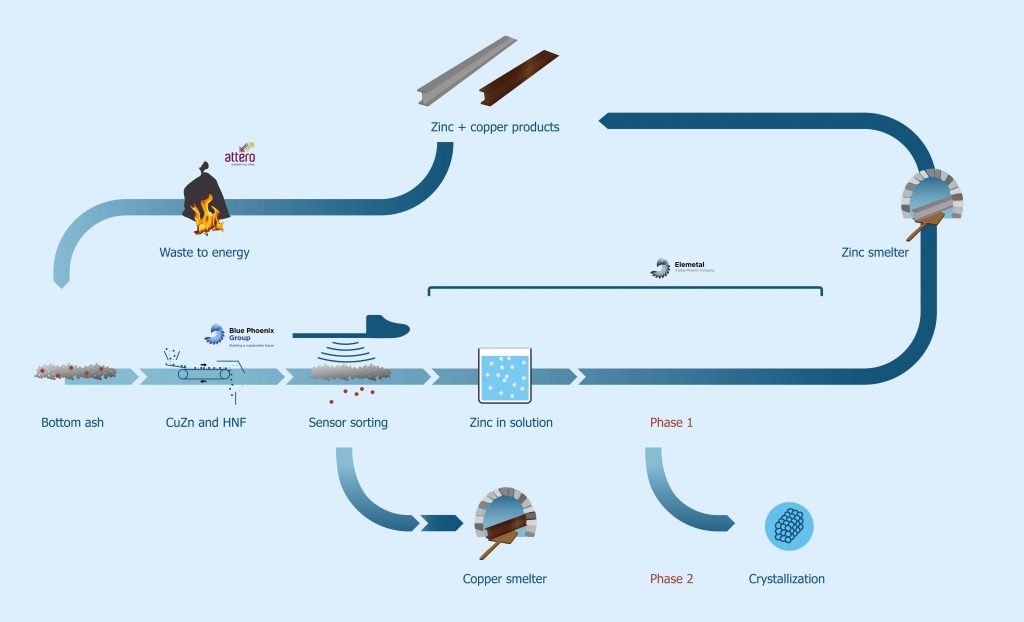

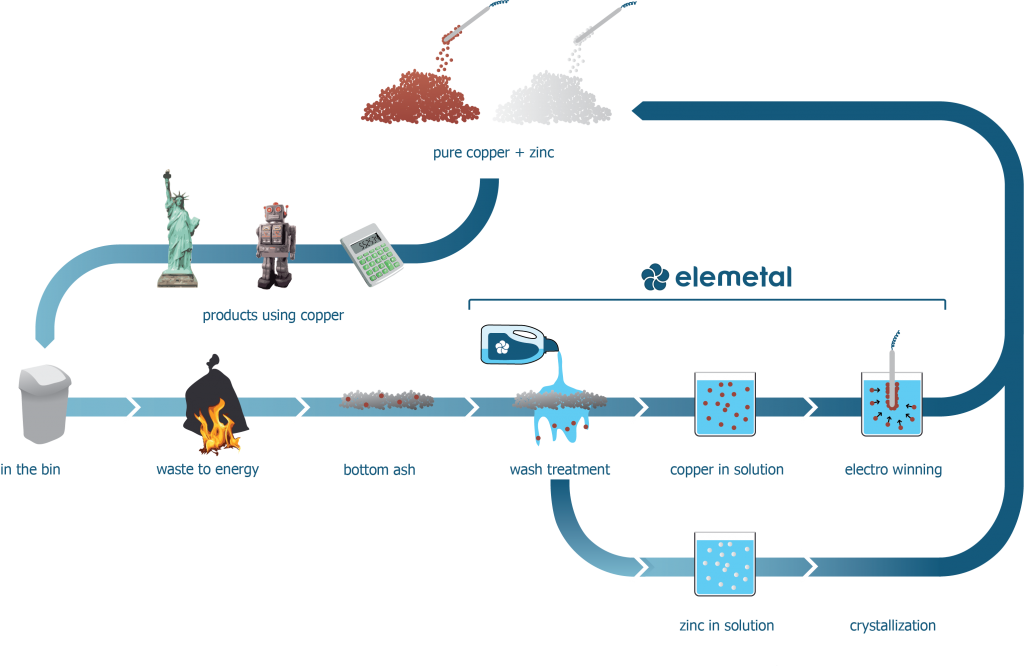

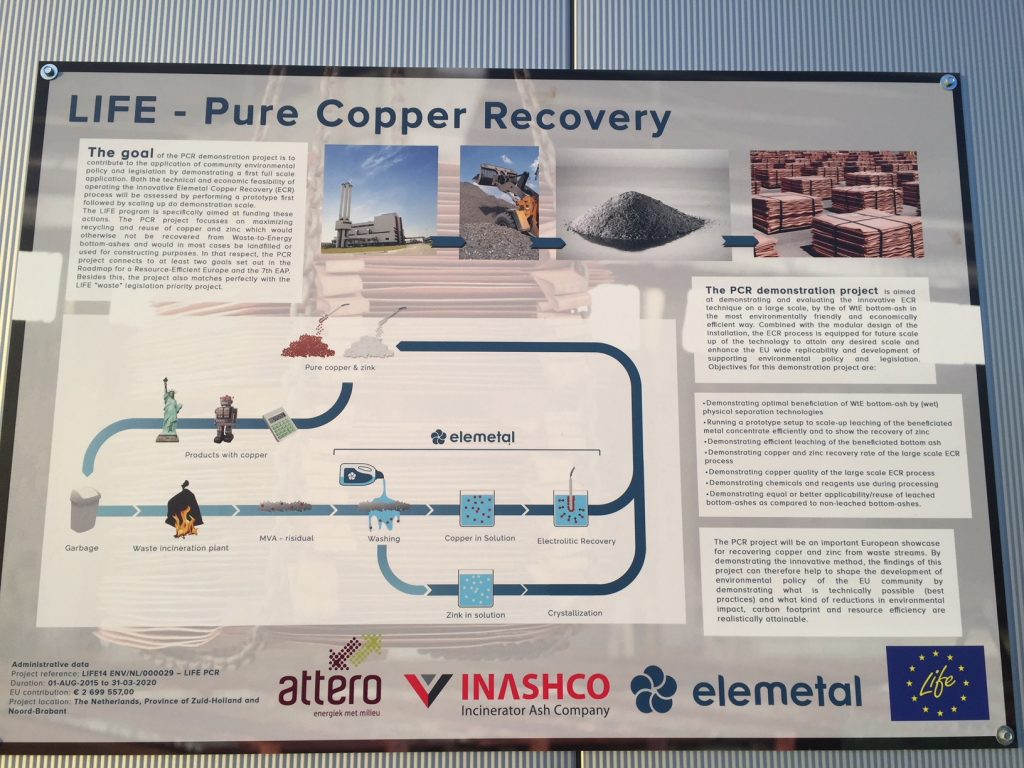

The PCR technology is bases on a leaching process followed by solvent extraction and electrowinning for copper. Together with Attero this concept was developed up to a pilot scale to proof feasibility. Today also more efficient (wet) physical separation technologies are available and under development leading to strong competition with the original developed PCR concept. This made Elemetal and Attero decide to apply the PCR technology more downstream in the value chain of bottom ash processing, where a more concentrated flow of copper is available. An extra benefit would also be the co-extraction of zinc which is significant available in these copper concentrates produced form bottom ash. The consortium aims to refine this copper and zinc into its pure metals by the PCR process. Through the years the PCR process made several iteration and now consists of a physical separation step (sensor sorting) followed by the hydrometallurgical process, which will be demonstrated within the LIFE project.

Project Summary

The goal of the PCR demonstration project is to contribute to environmental policy and legislation by demonstrating a first full scale application. The PCR project focusses on maximizing recycling and reuse of copper and zinc which would otherwise not be recovered from Waste-to-Energy bottom-ashes and would in most cases end-up at landfills or in civil construction works. During the project first a prototype is built to show the feasibility of the copper and zinc refining. This prototype will be followed by a demonstration in 2 phases. The first phase will focus on zinc leaching followed by a second demonstration where the process is extended to increase capacity and to come to an improved zinc derivative product.

Timeline

-

Publication of Layman’s report (March 2022)

-

Demo Phase 2 (November 2021 – March 2022)

-

Engineering, construction commissioning phase 2 (July 2020 – October 2021)

-

Results DEMO phase 1 ready (September 2020)

-

Website 2.0 online (Juli 2020)

-

Notice board in place (March 2020)

-

Relocation to new Demo site PlantONE, Botlek (Januari - April 2020)

-

Demo Phase 1 (September 2019 – December 2020)

-

Engineering and construction (January - June 2019)

-

Prototype testing (April – October 2017)

-

First website online (December 2015)

-

Notice board in place (AUGUST 2015)